Have you ever used a hydraulic bar cutter before? Should you work for a business your location building structures for example skyscrapers, homes, as well as tunnels, rebar is commonly used everyday. The strength that hydraulics gives you can make it so simple to cut through this metal. That’s why men and women will invest thousands of dollars in a good machine. A few of the machines are hand-operated like the portable rebar cutters, and there are people who are stationary and fully programmable. If you would like get the most power when cutting through rebar, a hydraulic bar cutter certainly is the machine that you might want to work with.

An Introduction To How They Work

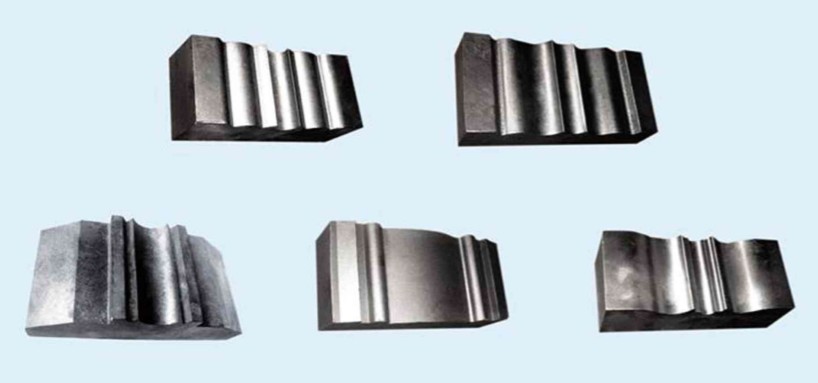

These machines are quite simplistic within their design, at the very least in how they are used. There is a motor that uses hydraulics as a form of power. These machines, particularly the portable ones, are utilized in factories, construction sites, as well as in mines. They are really easy to use and then make it really easy for that workers that must use them. Most of them can adapt to the type of bars that you are cutting through. This might be steel rods, round bars, or even deformed steel bars cut by steel bar cutters. Everything will be cut within seconds. They typically run using 220 V/110 V, and have a cutting speed of just below three seconds. Which means a single person could actually got through 20 pieces in less than a minute, and 1200 pieces inside an hour. In fact, you could see learn about how they work in this website: http://ellsenrebarcuttingmachine.com/hydraulic-rebar-cutter.

Hydraulic bar cutter for sale

Features On Hydraulic Rebar Cutters

Some of the best features will likely be how fast portable hydraulic rebar cutters may cut through this metal. They also have a swivel which lets you cut at different angles. These are very easy to use and hold. There is a trigger at the back, and a handle about the side rendering them very easy to operate. Just insert the rebar, pulled the trigger, as well as the machine will take it from there.

Do You Know The Used For?

The primary ways to use cutting through rebar, and that can be used for numerous things. Whenever you are establishing a foundation, or should you be in charge of perhaps creating the molds to the sides of buildings which can be being created, reinforcing bar must be put into the concrete mix. Whatever the purpose, they can be there to reduce through this material at the earliest opportunity which will help you boost your production levels. Provided that you can have them through the best company, possibly the largest that sells them for your lowest cost, you will certainly be very happy together with your purchase and your workers may help your organization generate more profits.

It’s actually very readily available these available for purchase. However, if you require a great deal of them, and also you want the absolute best rebar cutter machines companies in China could be the businesses that you have to work together with. It’s easy to place your order to find the state-of-the-art hydraulic bar cutters sent straight to you from firms that are the most effective with this industry.

For builders, contractors, fabricating plants, it is important to have

For builders, contractors, fabricating plants, it is important to have