Plastics are lightweight, inexpensive as well as durable materials. They can also be easily moulded into a wide range of products that are then used in different applications. As a result, the production of plastic materials has increased significantly in the last decades. However, the high levels of plastic use and their disposal bring about several environmental problems. About 4% of the gas and oil production, a non renewable resource is used as raw material for plastic and a further 5 per cent is used to provide energy for the manufacturing process.

Most of the plastic produced every year is used to make disposable items packaging or other items that are disposed within the year of manufacture. These two uses indicate that the use of plastic is not sustainable. In addition, due to the durability of polymer used, a substantial quantity of the disposed plastics accumulate as debris in natural habitats and landfills worldwide.

Plastic recycling is one of the best action available today to help reduce the impact of disposed plastics and waste plastic recycling machinery represent a dynamic area in the industries today. Plastic recycling reduces the quantity of waste requiring disposal, reduces carbon dioxide emissions and oil usage.

To start a plastic recycling plant, you should take the total recycling cost into consideration. This article outlines the major factors that affect plastic recycling plant price.

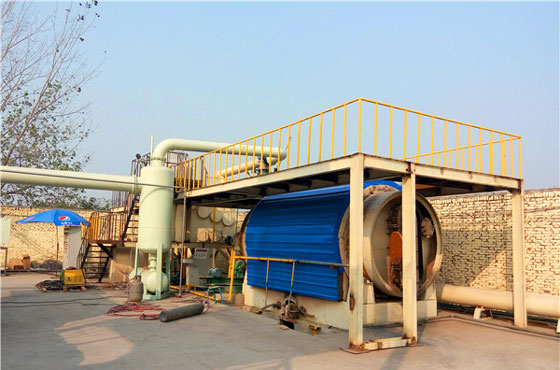

· Plastic Recycling Pyrolysis Systems

They main thing that plastic recycling plants need is the right type of pyrolysis system. This is the system required to process the plastic materials. The systems come in different sizes and price ranges but the truth is, some manufacturers and brands are just above everyone else. The price of a specific system depends on its features and the same rule applies, you will always get what you are willing to pay for.

If you are pressed for cash at the beginning, it is best to start with a small pyrolysis plant then upgrade to a bigger one as the business grows. This also helps to reduce the operation cost.

· Employees’ compensation

The plastic recycling industry is labour intensive and well as risky due to the injuries and accidents associated with the operations. As a result, the employees compensation rate are extremely high which increases the operation cost especially when handling low value recyclables such as waste plastic.

· Transportation cost

Transportation cost of recyclable plastic significantly affects the total operation cost. If the waste plastic pyrolysis unit is located in the rural areas, tit will result to higher transportation cost leading to high operation cost.

After purchasing the system, you will need to learn how the system operates by either visiting other recycling plants to learn how their equipment work and how they are run.

Manufacturers of pyrolysis systems have lots of information as well as data on the processes used, how to handles the equipment properly and the best practices to use as the industry.

To reduce cost, it is best to have a few employees attend training on how to operate the system then they can train the rest of the employees.

· Other costs

The plastic recycling price is also affected by other costs such as the system cost transportation costs, maintenance fees, electric charges among others. The higher these costs are, the higher the plastic recycling plant price.