The world today faces a serious plastic pollution problem. Perhaps this is because plastics are relatively inexpensive and very durable, meaning that they have become commonplace in the society. The main disadvantage of plastics is that they are slow to degrade, so they inevitably accumulate in our environment unfavorably affecting lands, waterways and oceans. Living organisms die from entanglement, ingestion of plastic waste as well as from exposure to plastic chemicals that are found in plastics.

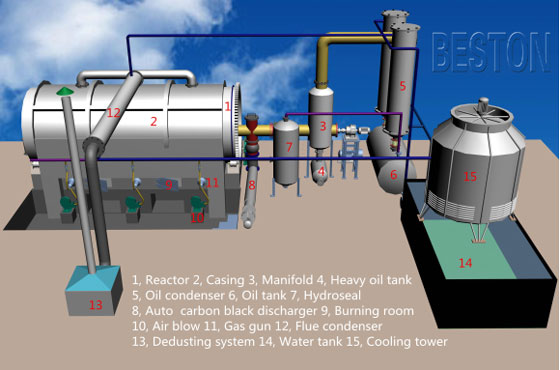

One solution to this problem is pyrolysis reactor design. Also called depolymerization, it is the process by which waste plastics are converted back into oil which can then be used as fuel. This technology is being embraced by the waste management industry so as to divert more plastics from landfills. In keeping with our commitment to environment protection and conservation, we have developed a highly efficient continuous waste plastic recycling plant which greatly saves time, labor and cost.

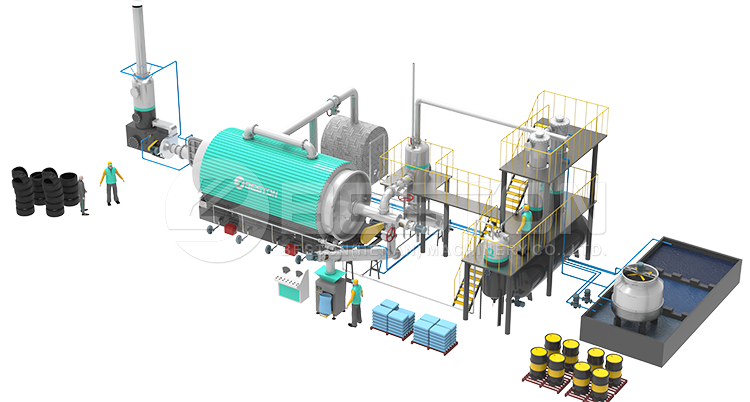

Equipped with an automatic feeding and discharging system, our continuous pyrolysis plant is able to operate without stopping it for input of materials or for emptying the slag from the other side. This means that it can work for 24 hours nonstop, enabling you to realize your targets.

The plant is highly formidable and versatile because it can convert waste plastic, tires and rubber into oil, carbon black and gas. For every 5 tons of raw materials, you get 2 tons of oil, requiring about 5 hours of processing time without any labor required. This means that 2 or 3 units of the continuous waste plastic pyrolysis plant installed in a municipality can play a very significant role in reducing the accumulation of plastic waste in the community.

The machine comes equipped with strong safety devices such as an alarm when temperature and pressure reach a certain threshold, an automatic pressure releasing system, firefighting devices and a dedusting system which can guarantee the safety of your workers and the machine itself. You also get to save energy and reduce environmental pollution in the process.

So far, our continuous waste tyre pyrolysis plant has been exported to many countries around the world such as Poland, South Africa, Canada, India, Kenya, Sweden, Malaysia, Nigeria, Ecuador, Brazil and many more. Our machines are very popular because there are many models which fit the requirements of a wide range of clients.

You will be pleased to know that the continuous waste plastic pyrolysis plant comes with one year warranty, assistance in site design, periodic calls by our engineers as well as one technician to help you during installation, testing and training your workers. Talk to us today and experience excellence in manufacturing and customer support. Or click this link: https://www.bestongroup.com/ to know more.

Waste tyre and plastic is quite often recycled and this is the preferred method to deal with waste plastic. Pyrolysis to extract fuel is also an alternative to recycling and is a process that can help the environment by preventing such waste tyre and plastic going to landfills. This diesel also helps to reduce the dependence on fossil fuel and extraction processes for oil. It is necessary to establish a definite and reliable source of tyre and plastic waste before any attempts to set up a waste tyre and plastic to diesel machine for the purpose of producing diesel. You can see the process on this page

Waste tyre and plastic is quite often recycled and this is the preferred method to deal with waste plastic. Pyrolysis to extract fuel is also an alternative to recycling and is a process that can help the environment by preventing such waste tyre and plastic going to landfills. This diesel also helps to reduce the dependence on fossil fuel and extraction processes for oil. It is necessary to establish a definite and reliable source of tyre and plastic waste before any attempts to set up a waste tyre and plastic to diesel machine for the purpose of producing diesel. You can see the process on this page